Our Services

The company has more than 100 sets of various high-precision machining equipment, covering CNC machining centers, CNC lathes, milling machines, grinders and other models.

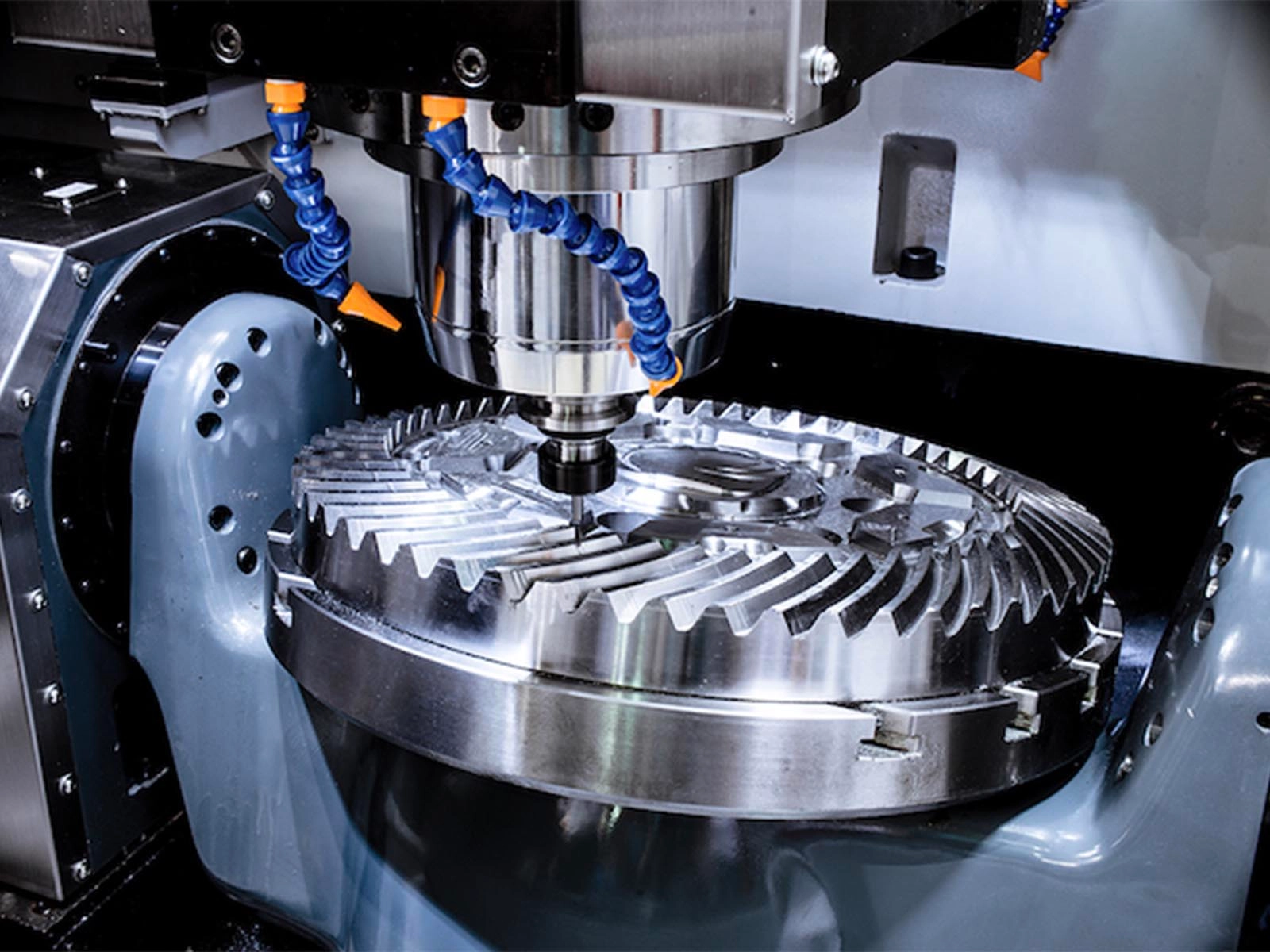

CNC Machining

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers and CNC Lathe machine …

Custom Mold

The selection of materials directly affects the lifespan, accuracy and applicable scenarios …

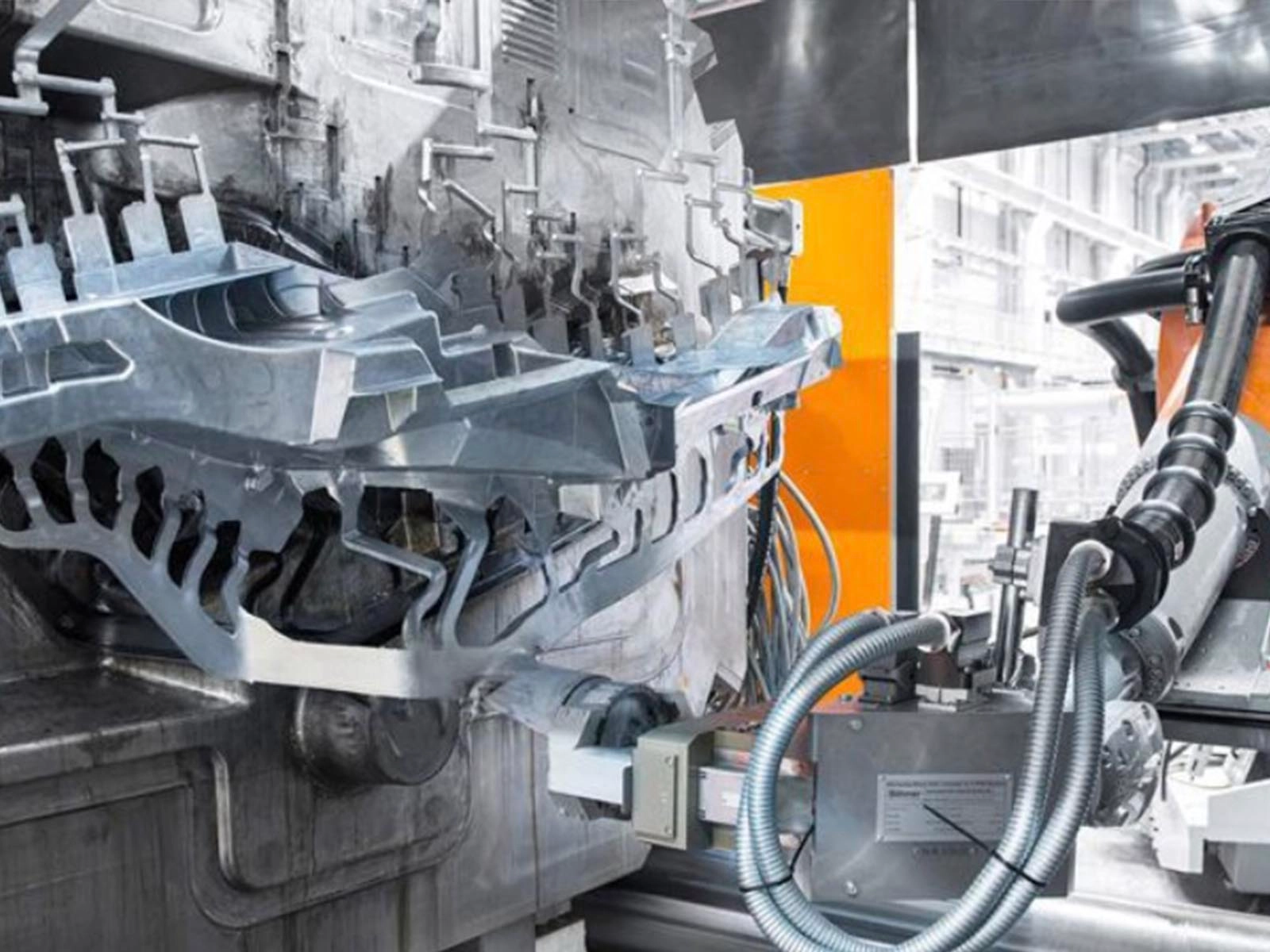

Die Casting&Gravity Casting

Our 2000T to 12000T cold chamber die casting machines, vacuum systems, and precision …

Sheet Metal Fabrication & Stamping

Our 200T to 2500T servo presses, 15-station progressive dies, and automated finishing …

About Us - China CNC Machining Service & Manufacturing

Dongguan Senfa Precision Machinery Co.,Ltd. is a modern enterprise focusing on precision machining and manufacturing,dedicated to providing customers with high-quality,high-precision machining solutions.

Establishment Time

Cover an Area

Sets

Development Technicians

Cooperative Brands

Business field — Automotive

For the traditional Fuel Vehicle, aluminum die castings can be used in engine systems, filter systems, air conditioning systems, shock absorption systems, braking systems,ABS systems, power steering control systems, and motors. We are mainly focusing on the production of engine accessories, transmission parts, wiper and seat accessories.

Electric Vehicle is made up of three main segments: traction motor, battery pack, and electrical control units.As a professional casting manufacturer, we produce some critical parts for the traction motor and battery pack, such as the motor housing,controller housing, battery case, DC-AC Converter, charger bracket, and others.

Automotive Industry

Value proposition:

Empowering the performance upgrade of automotive parts with precision machining technology, achieving a perfect balance between lightweight and high strength.

Core capabilities:

lCNC machining: Using a five-axis linkage machining center to achieve one-time clamping and forming of complex parts such as engine cylinders and gearbox housings, with tolerances controlled within ±0.005mm, ensuring the precise fit and efficient transmission of parts.

lDie casting and stamping: Using high-pressure casting combined with heat treatment technology to produce lightweight parts such as aluminum alloy suspension brackets, while reducing weight by 30%, the tensile strength reaches 350MPa, significantly improving the fuel economy and handling stability of the vehicle.

Why Choose Us?

Dedicated to providing customers with high-quality,high-precision machining solutions.

Strong Production Capacity

Equipped with 100+ high-precision CNC machining centers, turning and milling machines, covering the full range of metal / plastic / composite material processing, with micron-level precision guarantee.

Strict Quality Control

Professional quality inspection team + coordinate measuring machine (CMM) / projector / hardness tester, perform "triple inspection", and promise "zero defect" delivery standards.

Expert Technical Empowerment

The technical team responds to needs quickly within 48 hours and provides customized solutions for the entire process from drawing analysis to process optimization.

In-depth Customer Service

With "customer demand driven" as the core, we set up an exclusive customer service team to provide lifelong technical consultation, with customer satisfaction reaching more than 98%.

What Our Customers Say?

We undertake customized orders for military-grade UAV drive shafts, delivering 200 sets of finished products in 22 days. Our products are certified to China’s GJB 9001C Military Quality Management System, with zero failure rate during continuous operation under low temperature (-60℃) and high temperature (80℃) conditions.

German Customer: Customized UAV Drive Shafts

Their technical team provides a disruptive solution! By optimizing the transmission structure, the equipment accuracy is improved by 40%, and the whole process is debugged on site, and the technical support is an industry benchmark.

US Customer: Automation equipment upgrade cooperation

We customized 300 sets of precision laparoscopic forceps parts for a multinational medical group, completing the process from drawing optimization to finished product delivery in 18 days. The entire batch has passed ISO 13485 Medical Device Quality Management System certification, with dimensional tolerance controlled within ±0.005mm.

Southeast Asian Customer: Customized Minimally Invasive Surgical Instrument Parts

Put your parts into production today!

Precision in Every Part, Excellence in Every Service – Your Trusted Partner in Global CNC Machining