CNC Machining Services

We provide precision CNC machining services with 3-axis, 4-axis, and 5-axis milling, turning, and CNC lathe capabilities, delivering custom parts to your exact specifications.

Home > CNC Machining Services

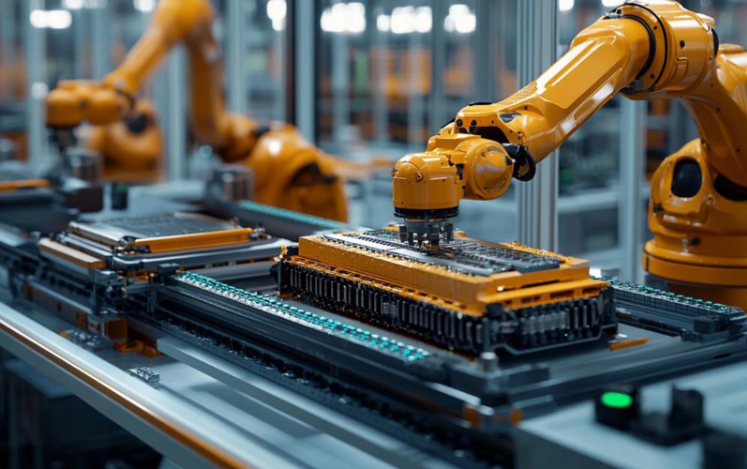

CNC Machining Service Introduce

SenFa provide professional CNC machining services for both prototypes and end-use parts, handling projects from simple components to highly complex geometries. With advanced 3-axis, 4-axis, and 5-axis milling centers, turning centers, CNC lathes, EDM machining, drilling, and precision grinding, we deliver tight tolerances and exceptional surface quality. By strictly following dimensional, shape, positional, and fit tolerance requirements, every part is produced to meet your exact specifications. Our ISO 9001-certified processes ensure consistent quality, reliable performance, and on-time delivery from small batches to full-scale production.

CNC Machining Services for Custom Parts

CNC Milling

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Materials for CNC Machining

METALS

Stainless Steel

Stainless steel is resistant to rust and staining, making it perfect for kitchen appliances and medical equipment. Its strength and aesthetic appeal also make it a popular choice for architectural designs and automotive parts.

Alloy Steel

Alloy steel offers enhanced strength and toughness through alloying elements like chromium or nickel. It is widely used in structural components, automotive crankshafts, and heavy machinery parts requiring superior load-bearing capacity.

Tool Steel

Tool steel is engineered for exceptional hardness and wear resistance, making it essential for manufacturing cutting tools, dies, molds, and high-stress industrial components. It retains performance at elevated temperatures.

Copper

Copper exhibits superior electrical and thermal conductivity, coupled with corrosion resistance. It is commonly used in electrical wiring, heat exchangers, plumbing systems, and artistic sculptures.

Magnesium

Magnesium is the lightest structural metal, featuring high strength-to-weight ratio and vibration damping. It is favored in aerospace, automotive lightweight components, and portable electronics enclosures.

Aluminum

Aluminum is a common metal material in CNC processing. It features light weight, high strength, and good thermal conductivity, and is suitable for manufacturing components in fields such as aerospace and automobiles.

Steel

Steel possesses high strength and wear resistance, and is suitable for manufacturing mechanical parts, automotive parts, and other engineering applications with strict requirements.

Brass

Brass has excellent electrical and thermal conductivity and is often used in the manufacture of electrical connectors, instruments, meters, and bathroom accessories, etc.

Titanium

Titanium is heat-resistant and corrosion-resistant, making it a viable option for many industrial applications, such as medical implants and aircraft components.

PLASTICS

PoM (Delrin/Acetal)

PoM is a high-performance engineering plastic with excellent stiffness, low friction, and dimensional stability. It is ideal for precision gears, bearings, and conveyor systems requiring durability and minimal lubrication.

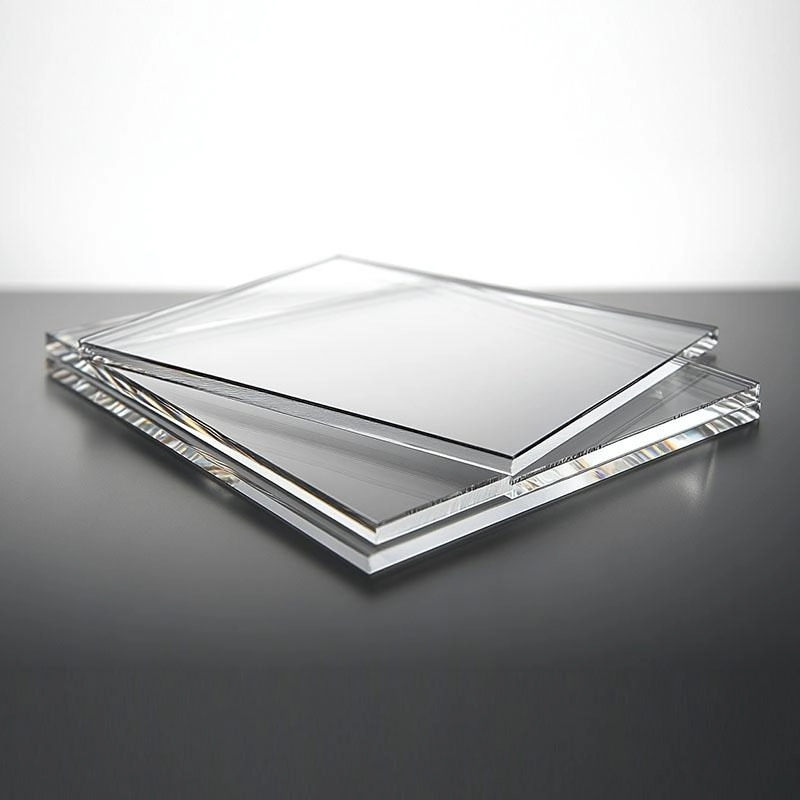

PMMA (Acrylic)

PMMA offers optical clarity and UV resistance, making it a premium alternative to glass. Applications include LED lenses, aquariums, signage, and medical devices requiring transparent components.

PEEK

PEEK is a high-temperature thermoplastic with exceptional chemical resistance and biocompatibility. It is used in aerospace bearings, semiconductor components, and implantable medical devices.

Nylon (PA)

Nylon combines abrasion resistance, self-lubrication, and fatigue endurance. It is widely adopted for gears, bushings, zippers, and textile fibers in automotive and consumer goods industries.

PTFE (Teflon)

PTFE is chemically inert with a ultra-low coefficient of friction. It is essential for non-stick cookware, chemical seals, and high-temperature electrical insulation in extreme environments.

PEl (Ultem)

PEI provides flame retardancy and high heat deflection temperature. It serves in aircraft interiors, medical sterilization trays, and microwave components demanding stringent safety standards.

PAl (Torlon)

PAI maintains mechanical strength at 275°C, making it the highest-performance engineering plastic. Critical applications include aerospace bearings, semiconductor wafer carriers, and Formula 1 brake systems.

PVC

PVC is a versatile and cost-effective plastic known for its excellent chemical resistance and durability. It performs well in applications such as piping, electrical insulation, and construction materials, providing long-term stability in harsh environments.

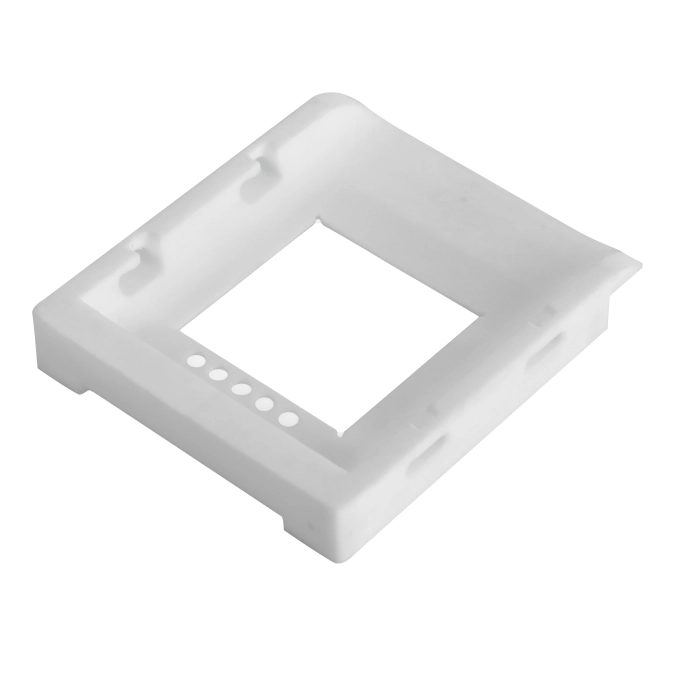

ABS

ABS is a tough, impact-resistant plastic with good dimensional stability and surface finish. It is widely used in consumer products, automotive parts, and prototyping, offering ease of machining and excellent paintability.

Advantages of CNC Machining Service

Material Selection

Choose from a wide range of over 50 certified materials, ensuring compatibility with diverse industries and specific application requirements.

High Precision Tolerances

Achieve consistently tight tolerances down to ±0.001 mm, guaranteeing parts that meet the most exacting standards.

Quality Assurance

Our manufacturing is backed by ISO 9001 and IATF 16949 certifications, ensuring reliable quality control and high-performance products you can trust.

Application

Automotive Industry

Value proposition:

Empowering the performance upgrade of automotive parts with precision machining technology, achieving a perfect balance between lightweight and high strength.

Core capabilities:

- CNC machining: Using a five-axis linkage machining center to achieve one-time clamping and forming of complex parts such as engine cylinders and gearbox housings, with tolerances controlled within ±0.005mm, ensuring the precise fit and efficient transmission of parts.

- Die casting and stamping: Using high-pressure casting combined with heat treatment technology to produce lightweight parts such as aluminum alloy suspension brackets, while reducing weight by 30%, the tensile strength reaches 350MPa, significantly improving the fuel economy and handling stability of the vehicle.

Aviation Field

Value proposition:

Breaking through the processing limits of aviation-grade materials and providing solid protection for flight safety.

Core capabilities:

- Custom molds: Combining 3D sand mold printing and vacuum quenching technology to manufacture titanium alloy turbine blade molds, the mold life is increased by 200%, ensuring the stable operation of the blades under high temperature and high pressure environments.

- Sheet metal processing: The skin stretch forming process is used to achieve high-precision processing of ultra-thin curved surface parts such as aircraft wing ribs, with a surface roughness of Ra0.4, meeting the strict requirements of aircraft for aerodynamic performance and structural strength.

Energy Equipment

Value proposition:

Overcome the manufacturing difficulties of extreme working conditions in the energy industry and ensure the long-term stable operation of equipment.

Core capabilities:

- Die casting and stamping: Use 12,000-ton large-scale die-casting machines to produce super-large-sized parts such as wind power bearing seats, with a single piece weight of 3.2 tons and an internal porosity controlled within 1%, significantly improving the load-bearing capacity and service life of the equipment.

- CNC machining: The dual-spindle milling and turning composite machining technology is used to achieve high-precision processing of large-sized parts such as nuclear power pipeline flanges, with a diameter of up to 2.5 meters and a flatness controlled within 0.02mm, ensuring the sealing performance and stability of the equipment in extreme environments.

Electronic Precision

Value proposition:

Support the miniaturization trend of electronic equipment with nanometer-level precision to meet the needs of high precision and high reliability.

Core capabilities:

- Sheet metal processing: Using 0.1mm ultra-thin stainless steel foil stamping technology, we produce micron-level structural parts such as 5G base station heat sinks, with hole spacing accuracy controlled within ±0.01mm to ensure heat dissipation performance and electromagnetic shielding effect.

- Custom molds: Combining PVD coating and mirror polishing technology, we manufacture high-precision molds such as semiconductor equipment vacuum cavities, with leakage rates controlled below 1×10⁻⁹Pa·m³/s, to ensure stable operation and long-term reliability of the equipment in a vacuum environment.

Medical Equipment

Value proposition:

Elevating medical equipment innovation with nanometer-precision engineering, ensuring uncompromising safety and reliability in critical healthcare applications.

Core capabilities:

- CNC Machining: Utilizing ultra-precision 7-axis CNC systems to manufacture implantable components (e.g., orthopedic joint interfaces, dental prosthetics) with surface finishes ≤Ra0.2μm and positional accuracy ≤±0.003mm, meeting ISO 13485 biocompatibility standards.

- Precision Injection Molding: Employing medical-grade liquid silicone rubber (LSR) injection technology to produce microfluidic chips and catheter parts with 0.1mm wall thickness, 100% defect-free rate under automated vision inspection.

Why Choose Us?

Dedicated to providing customers with high-quality,high-precision machining solutions.

Strong Production Capacity

Equipped with 100+ high-precision CNC machining centers, turning and milling machines, covering the full range of metal / plastic / composite material processing, with micron-level precision guarantee.

Strict Quality Control

Professional quality inspection team + coordinate measuring machine (CMM) / projector / hardness tester, perform "triple inspection", and promise "zero defect" delivery standards.

Expert Technical Empowerment

The technical team responds to needs quickly within 48 hours and provides customized solutions for the entire process from drawing analysis to process optimization.

In-depth Customer Service

With "customer demand driven" as the core, we set up an exclusive customer service team to provide lifelong technical consultation, with customer satisfaction reaching more than 98%.

FAQ

Q: What materials can you machine?

A: We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics, composites, and more. If you have a special material request, feel free to contact us.

Q: How do you ensure the quality of CNC machined parts?

A: We implement strict quality control processes using advanced inspection equipment such as CMM, surface roughness testers, and optical comparators. Each part is verified against your specifications before delivery.

Q: Can you handle complex geometries and tight tolerances?

A: Yes, our 3 to 5-axis CNC machines enable us to machine complex shapes and maintain tight tolerances, meeting demanding engineering requirements.

Q: Do you provide finishing services?

A: Yes, we offer a variety of finishing options including anodizing, powder coating, plating, polishing, sandblasting, and painting to meet your aesthetic and functional needs.

Q: Can you assist with design optimization for manufacturability?

A: Absolutely. Our engineering team provides Design for Manufacturability (DFM) feedback to improve your design for cost-effectiveness, ease of production, and quality