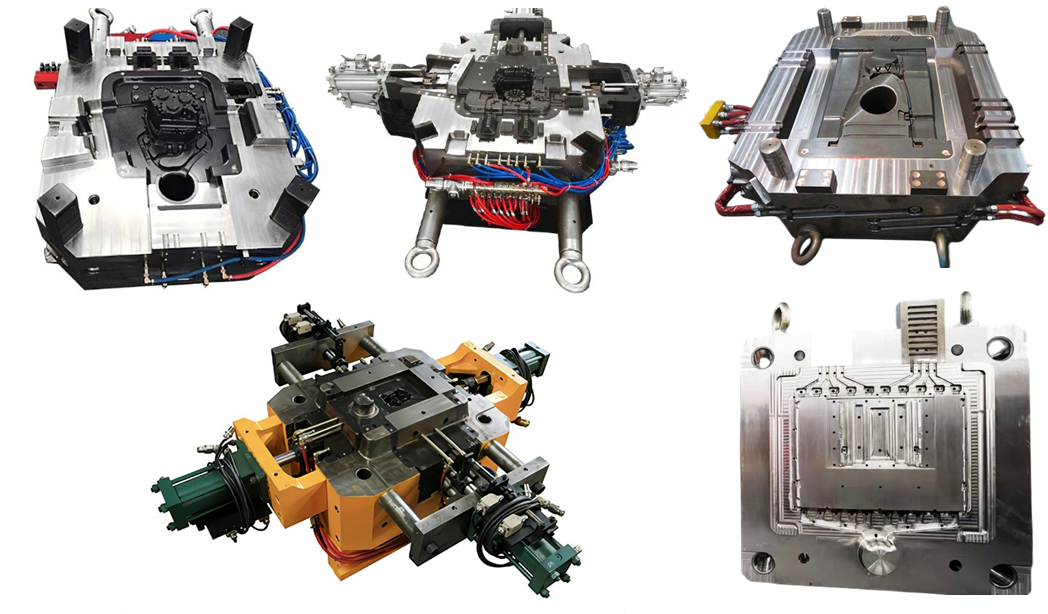

From small toy parts to large automotive components, standardized products made through mass production all rely on molds—the “mother machine of industry”. The rationality of mold design and the precision of mold manufacturing directly determine product quality, production efficiency, and costs, making them the core competitiveness of enterprises in the mass production process.

I. Mold Design: “Calculate Accurately” Before Taking Action

Design is the “soul” of a mold, with its core being the use of technology to avoid risks in advance. The key words are demand matching and simulation optimization.

• First, fully understand requirements: Clarify the product’s material (plastic/metal/rubber), dimensional tolerance, surface precision, and production volume—these form the foundation of design.

• Use software for “prediction”: Create 3D models with CAD, then simulate the molding process using CAE simulation to identify issues such as warping and shrinkage in advance, avoiding rework later.

II. Mold Manufacturing: Turning “Drawings” into “Precision Tools”

Manufacturing is the “framework” of a mold, with its core being the use of processes to ensure precision. The key words are micron-level processing and test molding verification.

1. Material selection: Choose the right mold steel (e.g., S136 plastic mold steel, H13 hot-work steel) to ensure mold hardness and wear resistance.

2. Precision processing: Achieve micron-level precision processing using equipment such as CNC machining centers, EDM (Electrical Discharge Machining), and wire cutting to create key components like cavities and cores.

3. Test molding and adjustment: After assembly, install the mold on equipment for trial production, check if samples meet standards, and make repeated adjustments until qualification to ensure stable mass production.

III. Choose the Right Partner to Avoid Detours

If your project requires customized mold design, high-precision mold manufacturing, or optimization of existing mold solutions, a professional team can help you:

• Quickly match requirements and shorten the design cycle;

• Strictly control processing precision and reduce mass production risks;

• Follow up on test molding throughout the process to ensure implementation results.

Accurate mold design + reliable mold manufacturing is the “assurance” for product mass production.