Resources

Home » Resources

Case Studies

Continental AG, Germany: Customized Brake System Sensor Case

Precision Machining of Automotive Safety Parts

As a global leader in automotive safety systems, Continental needed to customize a batch of brake pressure sensor components with a tolerance of ±0.003mm and required delivery within 30 days. A precision manufacturing enterprise completed the delivery of 5,000 pieces 2 days ahead of schedule through ultra-precision turning centers and a digital quality traceability system. The products passed the German DIN EN ISO 13485 medical-grade extended certification (special requirements for automotive safety parts) at one time, with a yield rate of 99.92%. Eventually, it became a strategic supplier for Continental in Europe, with its annual order share increasing to 25%.

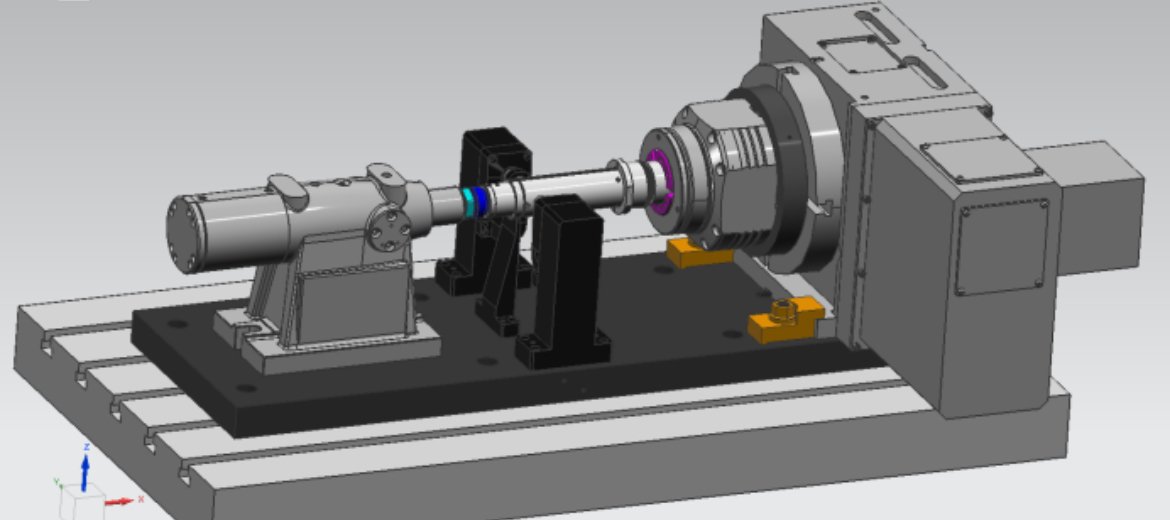

DENSO (Japan): New Energy Motor Shaft Parts Project

Intelligent Assembly Line Upgrade Project

For a hybrid vehicle’s high-speed motor, DENSO needed to customize titanium alloy shaft parts with a tolerance of ±0.002mm and require delivery within 40 days. A domestic enterprise optimized the vacuum heat treatment process and applied six-axis linkage machining technology. It not only delivered the products on schedule but also improved the dynamic balance precision of the parts to 1.5 times the industry standard. The products passed the Japanese JIS D 4401 automotive parts reliability certification. Subsequently, it obtained 30% of DENSO’s new energy shaft parts orders in China.

TRW (USA): Autonomous Driving Steering System Component Case

Bulk Procurement Project for Stainless Steel Brackets

TRW needed custom valve core components with a tolerance of ±0.004mm for the steer-by-wire system developed for L3-level autonomous driving vehicles, with a delivery cycle of 35 days.

A company completed the delivery of 2,000 sets of products 4 days ahead of schedule by leveraging an AI visual inspection system and flexible production line scheduling. The products achieved a yield rate of 99.85% and successfully passed the U.S. SAE J2954 safety certification for autonomous driving components.

Ultimately, the company successfully entered TRW’s North American supply chain and subsequently secured 30% of the prototype orders for steering system components in TRW’s global new vehicle models.

FAQs

Q: How to ensure the tolerance accuracy of precision machined parts?

A:Use a five-axis linkage machining center, combined with online measurement and closed-loop compensation system, to correct tool wear and thermal deformation in real time, and dynamically control the tolerance within ±0.005mm.

Q: What is the shortest delivery cycle for urgent orders?

A : Enable “Quick Response Channel”:

Q: Can you undertake non-standard customized mold design?

A :The 20-person senior team is good at:

Q: Is the price of die castings more advantageous than that of peers?

A :Price advantage achieved through triple cost control:

Q: How to deal with product quality problems?

A :”48-hour closed-loop processing of quality problems”: