CNC Machining

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers and CNC Lathe machine enable to make precise, high-quality CNC parts that fulfill your custom specifications.

Dongguan SenFa,Make Parts More Accurate!

Lower prices, higher quality, faster delivery speed - let us become your best business partner.

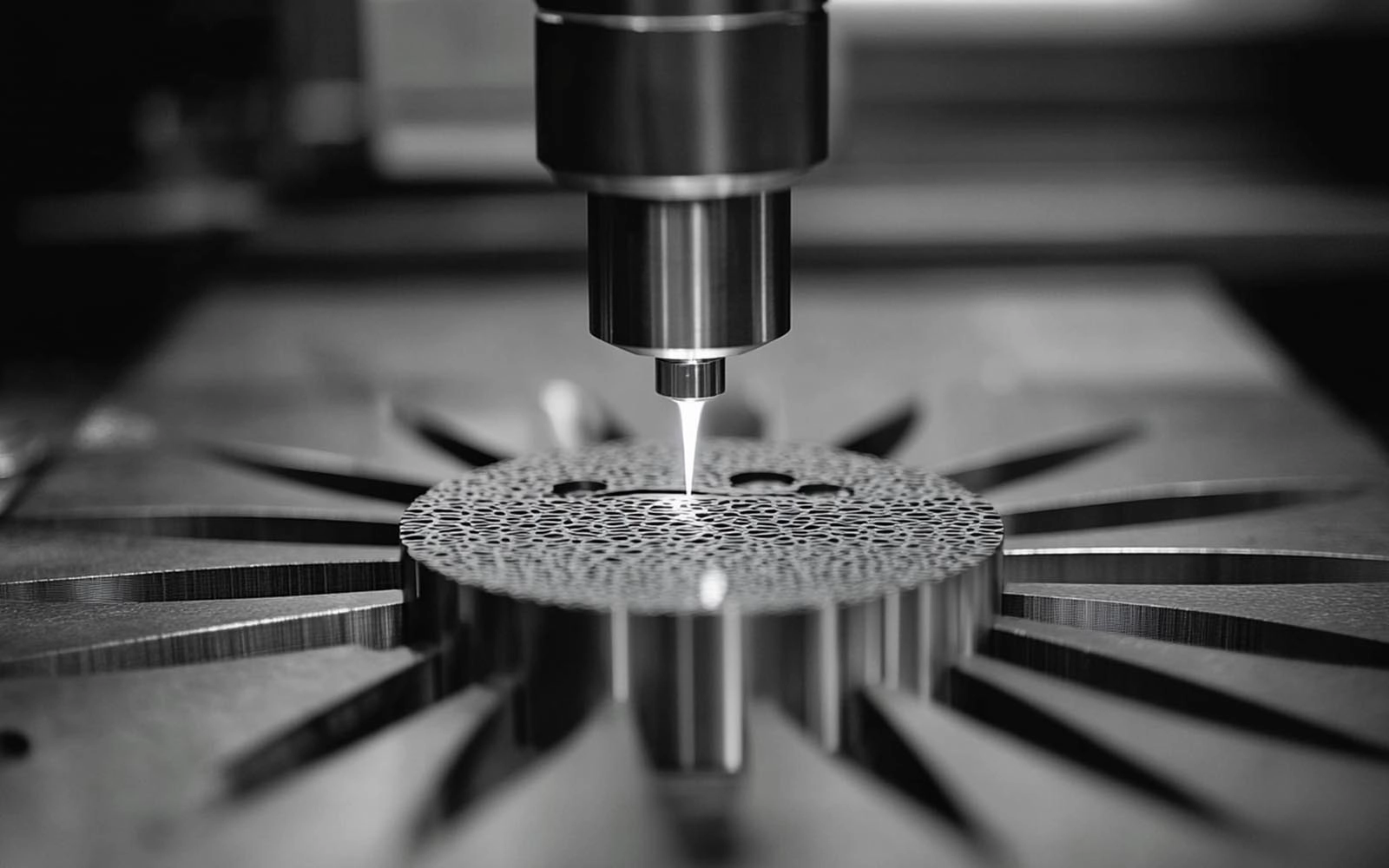

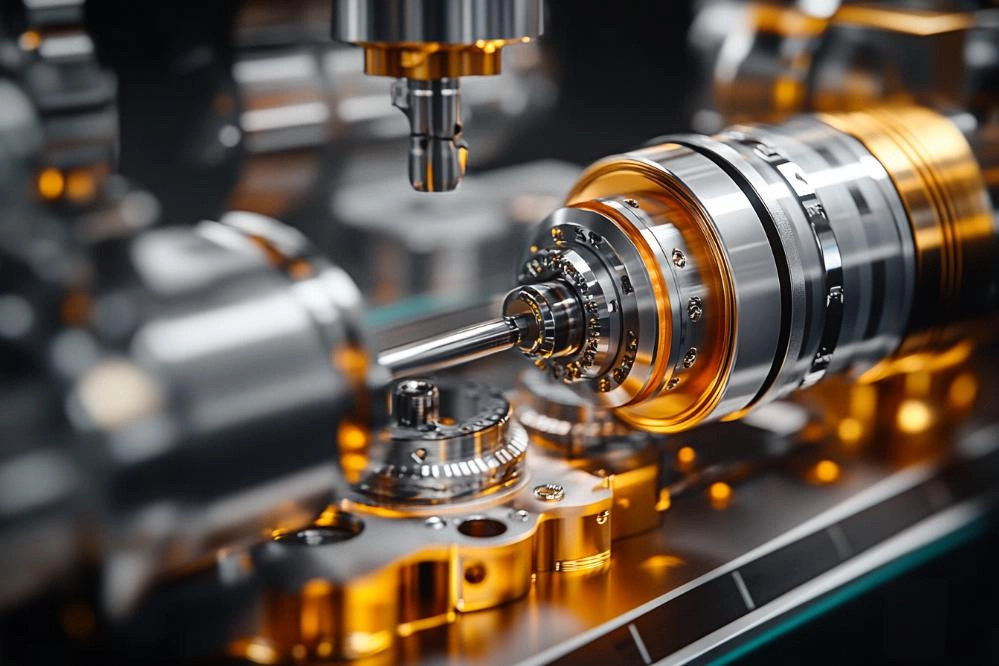

CNC Milling

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

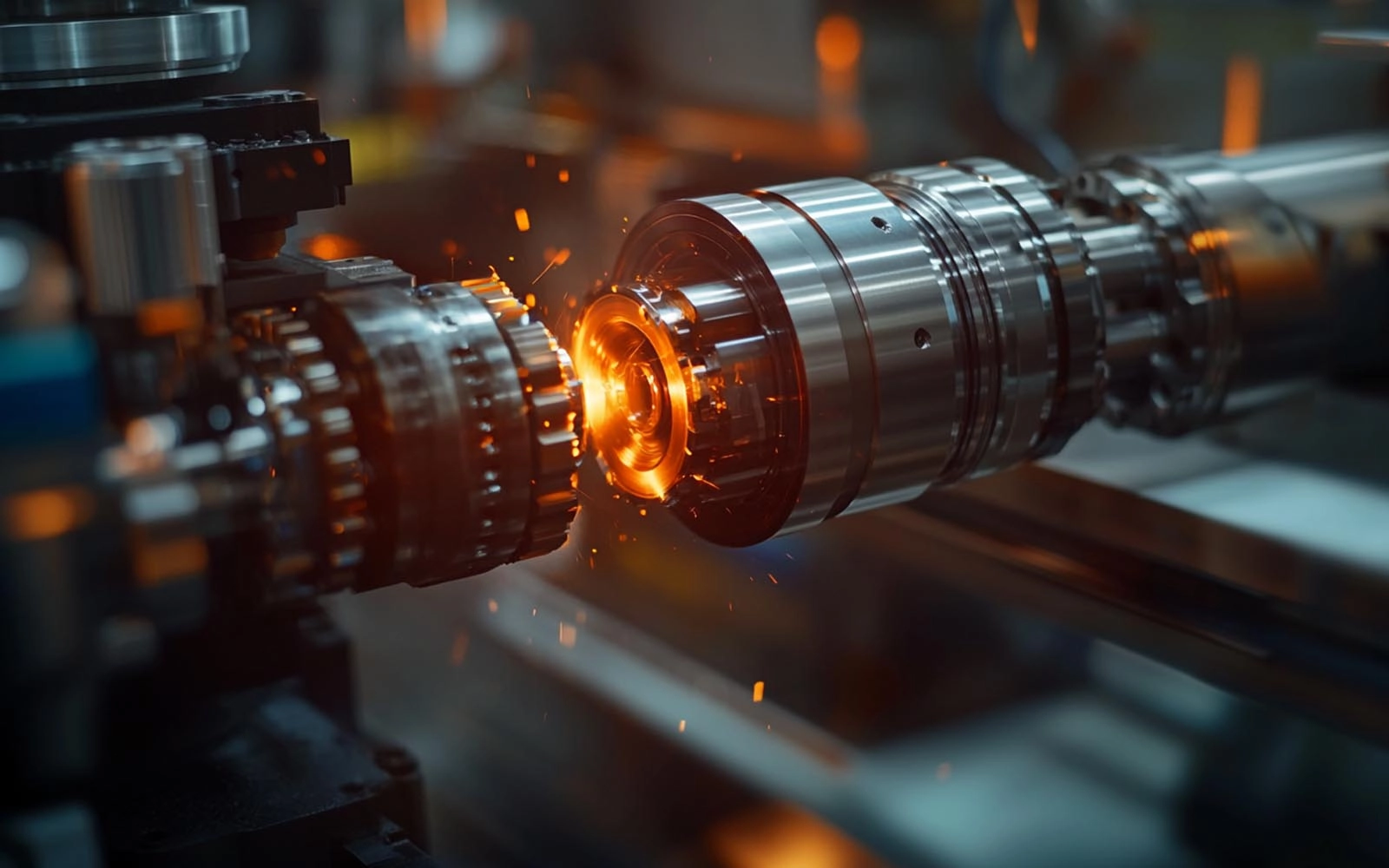

CNC Turning

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Finishes Service

Add multiple finishes to your parts, such as Anodizing, Sand Blast, Powder Coat, Plating, etc.

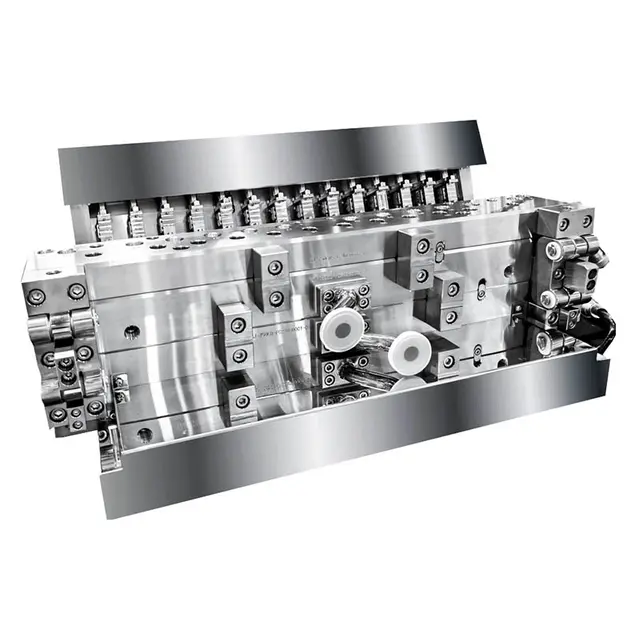

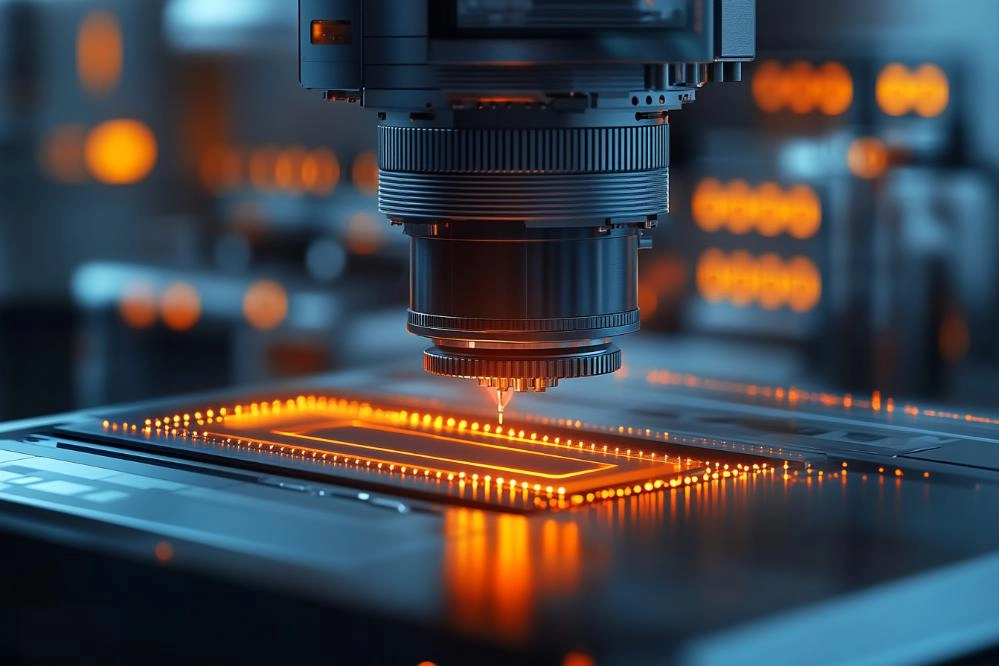

Wire EDM

Using the electrochemical etching principle to process high-hardness metals (such as mold steel), the accuracy can reach ±0.002mm.

Mirror EDM Machining

Achieves mirror finish with surface roughness ≤0.05μm Ra, used for precision molds.

CNC Grinding

Precision planing or cylindrical grinding, with a tolerance of ±0.0025mm. Suitable for parts with high surface finish requirements.

Case Study of Processed Products

CNC Machining Process

1. Needs Communication

Your Requirements Drive Production:Engineer 1 v 1 analyzes drawings, optimizes manufacturability (DFM suggestions), saving costs and avoiding pitfalls.

2. Intelligent Programming

CAM Software Generates Optimal Toolpaths:Automatically avoids interference, reduces machining time, enhances precision stability.

3. Rigorous Pre-Processing

Material Laser Inspection + Custom Fixtures:Eliminates raw material defects, clamping deformation <0.005mm.

4. Full-Process Machining

Precision 5-Axis Linkage Cutting:Rough machining: Rapid material removal → Finish machining: Mirror effect (Ra0.2μm optional).

5. Ironclad Quality Control

CMM Full-Dimension Comparison:Generates inspection reports for every part, automatic alarm for out-of-tolerance deviations.

6. Value-Added Post-Processing

One-Stop Surface Treatment:Anodizing/Sandblasting/Plating to meet functional and aesthetic needs.

Display of Processable Materials

The selection of materials is based on the customer’s requirements. We can process most of the materials available in the market.For more options, please feel free to contact us.

Material

Material

Introduction to Surface Treatment of Machined Parts

In addition to our custom CNC machining services, we offer a comprehensive range of surface treatment options for precision machined parts. From basic cleaning and deburring to complex electroplating or functional coatings, our variety is extensive, allowing you to select the optimal solution based on your specific requirements. There is no single "best" surface treatment – only the option "most suitable" for your unique application scenario.

What Our Customers Say?

We undertake customized orders for military-grade UAV drive shafts, delivering 200 sets of finished products in 22 days. Our products are certified to China’s GJB 9001C Military Quality Management System, with zero failure rate during continuous operation under low temperature (-60℃) and high temperature (80℃) conditions.

German Customer: Customized UAV Drive Shafts

Their technical team provides a disruptive solution! By optimizing the transmission structure, the equipment accuracy is improved by 40%, and the whole process is debugged on site, and the technical support is an industry benchmark.

US Customer: Automation equipment upgrade cooperation

We customized 300 sets of precision laparoscopic forceps parts for a multinational medical group, completing the process from drawing optimization to finished product delivery in 18 days. The entire batch has passed ISO 13485 Medical Device Quality Management System certification, with dimensional tolerance controlled within ±0.005mm.