Casting(Die Casting&Gravity Casting)

Our 800T to 3500T cold chamber die casting machines,Permanent Mold Gravity Casting Machine, vacuum systems, and precision CNC finishing enable high-volume production of complex metal parts that exceed industry standards.

Dongguan SenFa,Excellence in Gravity Casting & Die Casting: From Molten Metal to Precision Finished Products!

Lower prices, higher quality, faster delivery speed - let us become your best business partner.

High-Pressure Die Casting

Aluminum/Zinc/Magnesium alloys with wall thickness as low as 0.5mm

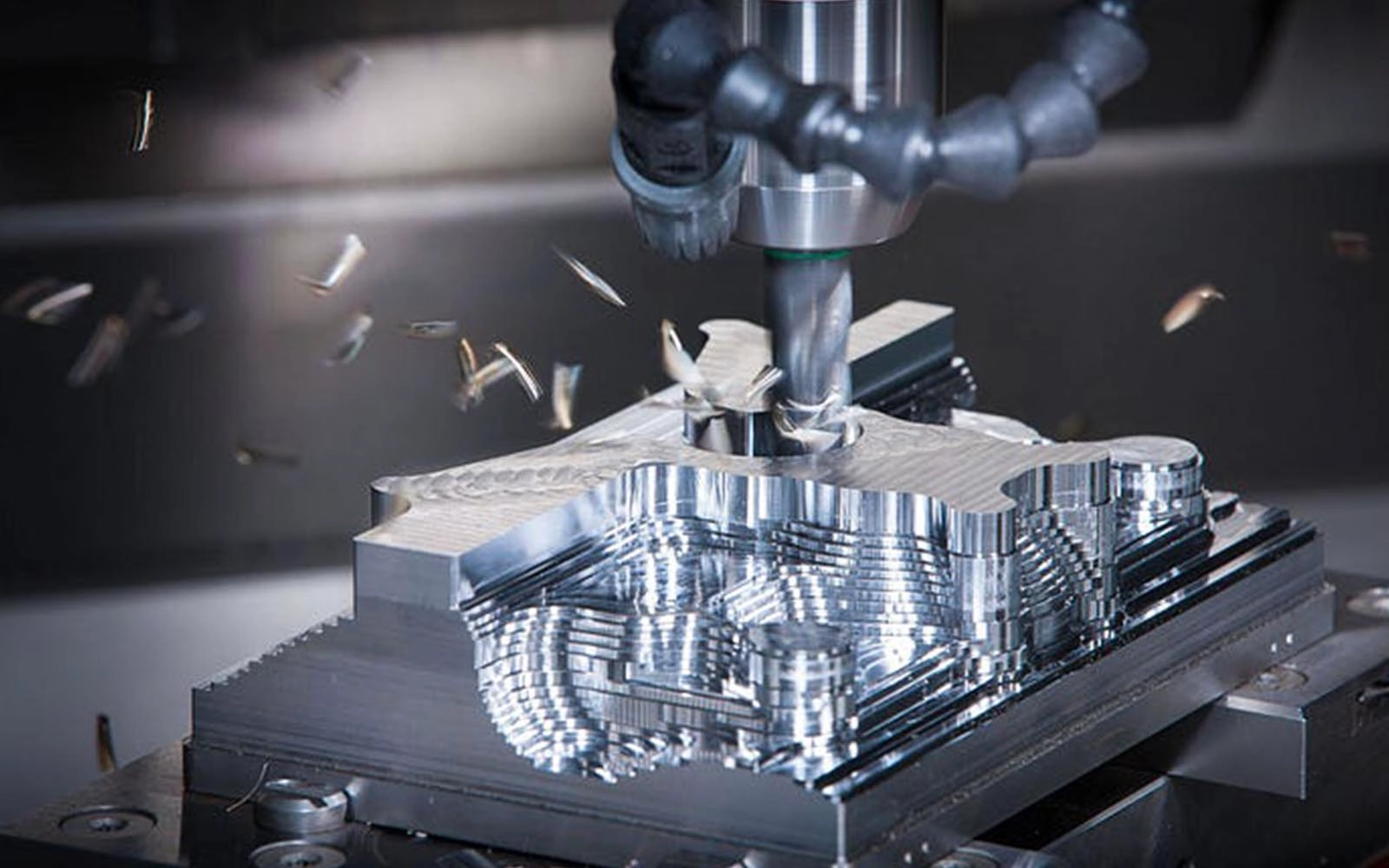

Precision CNC Machining

5-axis machining centers achieve ±0.05mm tolerance for critical features

Advanced Surface Finishing

Anodizing (Color customization) | Nanocoatings (Anti-corrosion 1000h+)

Tooling & Mold Making

H13 steel molds with 300,000+ shots lifespan

Quality Assurance

X-ray scanning: Detect 0.3mm³ internal defects

Case Study of Processed Products

Gravity Casting and Die Casting Processes

We have an excellent technical team, which can be designed according to customers requirements.

1. Requirement Co-design

DFM Drives Zero-Defect Starting Point

Engineers provide die-casting-specific DFM solutions through 1v1 3D drawing analysis:

Optimize draft angles/wall thickness/ribs —— Reduce shrinkage risk by 30% Intelligent simulation of metal flow —— Predict porosity location, extend mold life by 50%

2. Intelligent Die-Casting Programming

Dynamic Parameters for Precise Form Control

Cloud-based die-casting platform calculates optimal process chain in real-time:

Three-stage injection control: Slow-speed 0.3m/s degassing → High-speed 6m/s filling → Intensification 100MPa feeding Precise mold temperature zoning ±5℃ —— Eliminate flow marks/cold shuts

3. Ultra-Clean Preprocessing

Dual Safeguards for Quality Assurance

Alloy melt purification:

Argon degassing + density testing —— Hydrogen content ≤0.1ml/100g

Intelligent mold maintenance:

Automated nano-coating spray → Laser-calibrated mold temperature → Mold clamping gap <0.03mm

4. High-Pressure Precision Forming

10,000-Tonne Integrated Die-Casting

Fully automated die-casting island execution:

1200℃ molten metal injected in 3s → 1200T clamping force maintains form → Water-cooling system rapid cooling Micron-level precision control: Thin-walled parts ±0.15mm tolerance | Surface Ra1.6μm no grinding required

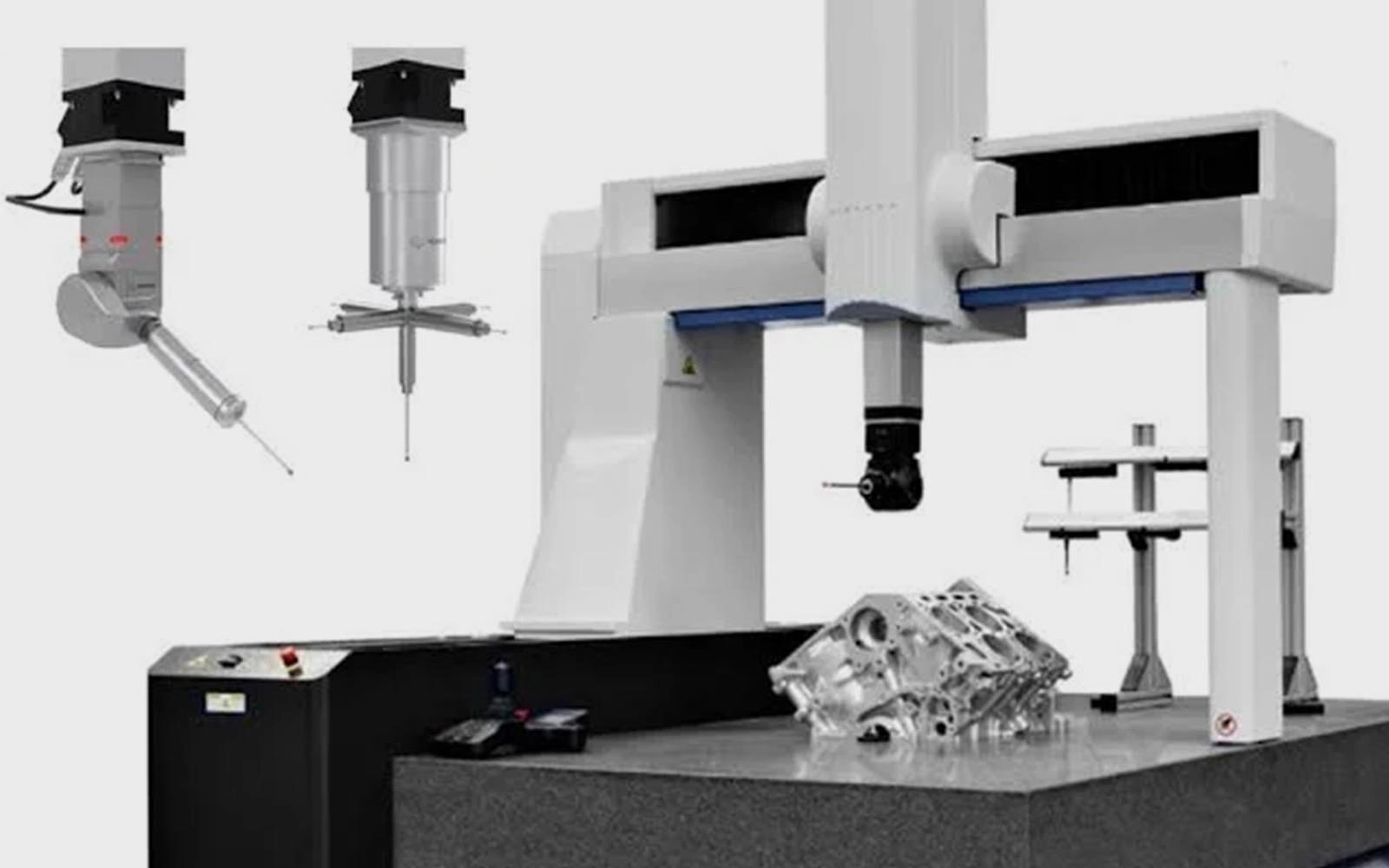

5. Full-Dimension Quality Inspection

X-ray + CMM Dual Assurance

Internal defect scanning:

Industrial CT layered detection —— Porosity identification accuracy 0.2mm³

Zero-tolerance dimensional control:

Online CMM measurement → 100% key dimension comparison → Automatic machine lock for 0.05mm deviation

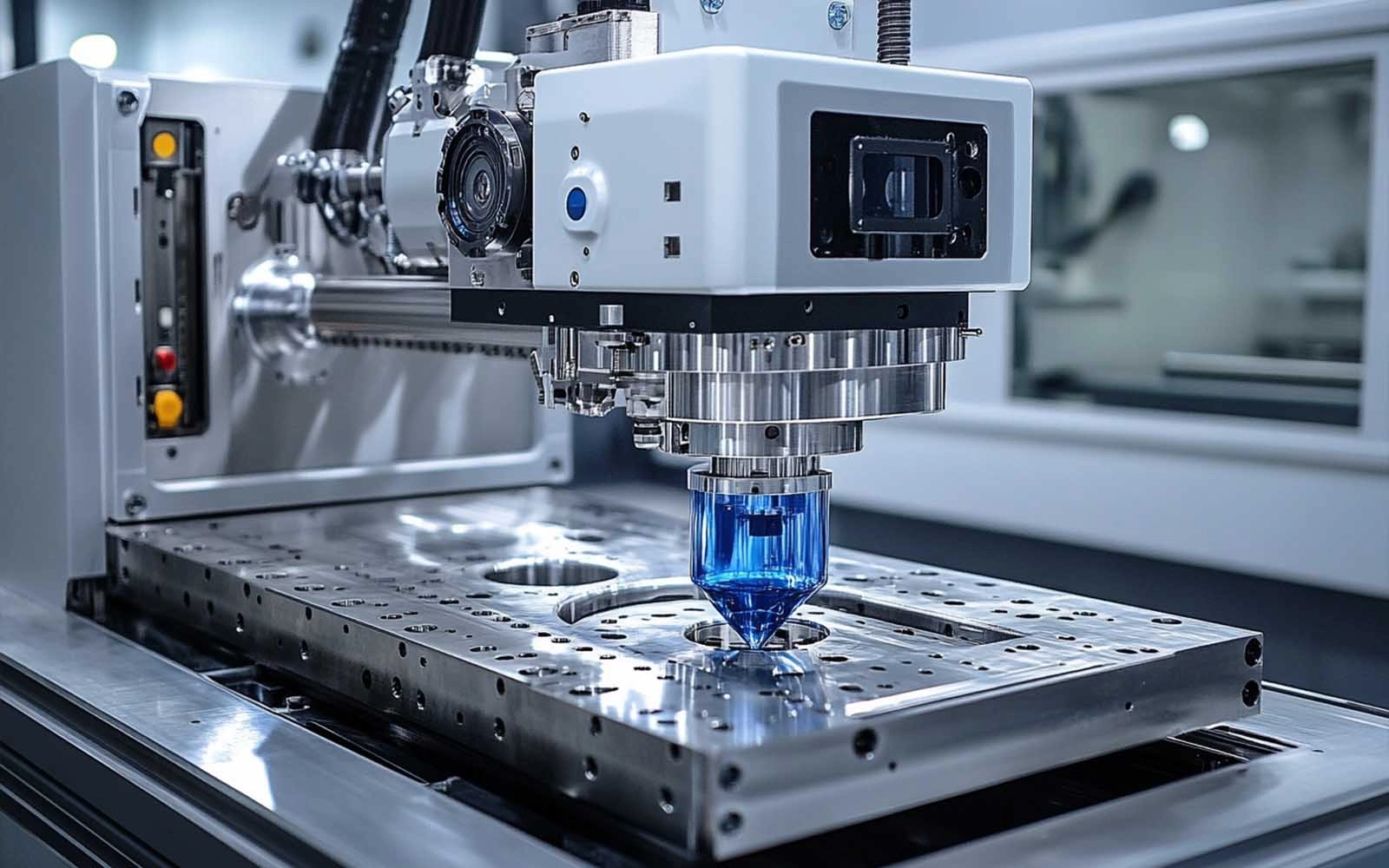

6. Value-Added Post-Processing

Functional & Aesthetic Dual Enhancement

One-stop surface solutions:

High-gloss diamond cutting → Nano-electroplating anti-corrosion (salt spray test 1000h+)

Medical-grade passivation | Custom color anodizing

Display of Processable Materials

The selection of materials is based on the customer’s requirements. We can process most of the materials available in the market.For more options, please feel free to contact us.

Introduction to Surface Treatment of Machined Parts

In addition to our custom CNC machining services, we offer a comprehensive range of surface treatment options for precision machined parts. From basic cleaning and deburring to complex electroplating or functional coatings, our variety is extensive, allowing you to select the optimal solution based on your specific requirements. There is no single "best" surface treatment – only the option "most suitable" for your unique application scenario.

What Our Customers Say?

We undertake customized orders for military-grade UAV drive shafts, delivering 200 sets of finished products in 22 days. Our products are certified to China’s GJB 9001C Military Quality Management System, with zero failure rate during continuous operation under low temperature (-60℃) and high temperature (80℃) conditions.

German Customer: Customized UAV Drive Shafts

Their technical team provides a disruptive solution! By optimizing the transmission structure, the equipment accuracy is improved by 40%, and the whole process is debugged on site, and the technical support is an industry benchmark.

US Customer: Automation equipment upgrade cooperation

We customized 300 sets of precision laparoscopic forceps parts for a multinational medical group, completing the process from drawing optimization to finished product delivery in 18 days. The entire batch has passed ISO 13485 Medical Device Quality Management System certification, with dimensional tolerance controlled within ±0.005mm.