Sheet Metal Fabrication & Stamping

*Our professional sheet metal fabrication equipment and expertise enable us to produce precise, high-quality sheet metal parts that meet your custom specifications

*Our 200T to 2500T servo presses, 15-station progressive dies, and automated finishing lines enable mass production of high-tolerance stamped parts at unmatched efficiency.

Dongguan SenFa,Make Parts More Accurate!

Lower prices, higher quality, faster delivery speed - let us become your best business partner.

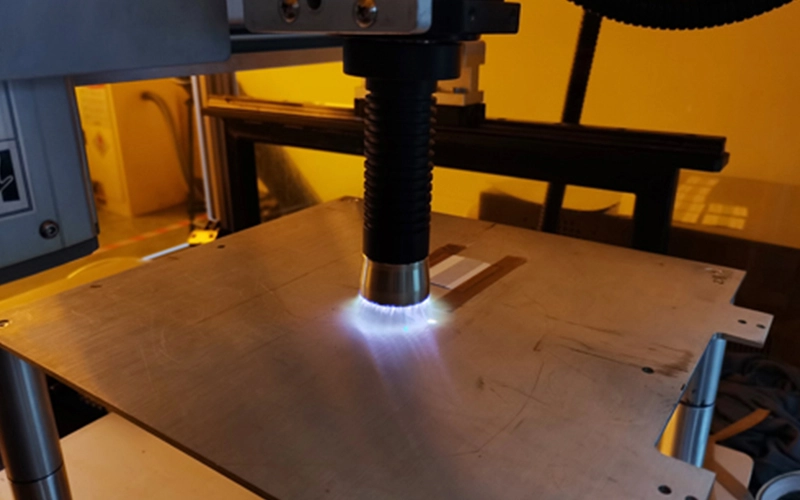

Laser Cutting

Cut the large sheet of metal into the required shape outline,High precision and high flexibility, suitable for complex contours and small to medium batch sizes.

Water Cutter Cutting

Cold cutting, no heat-affected zone, suitable for any material (including heat-sensitive materials), with large cutting thickness.

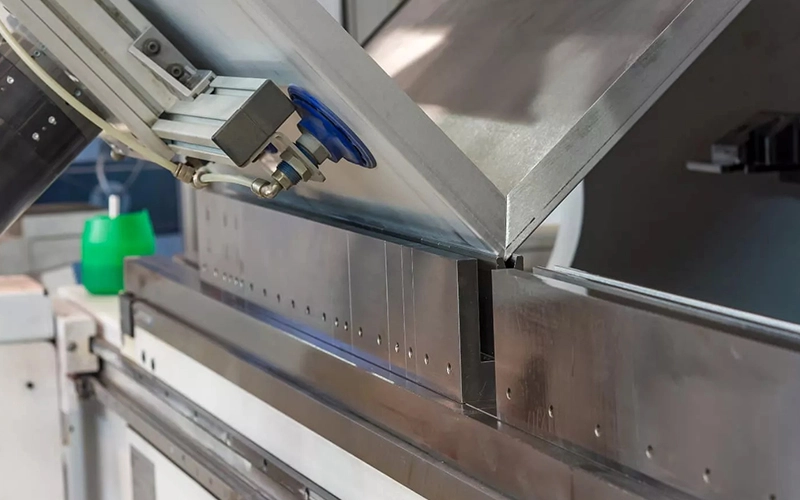

Bending

Shape the flat sheet materials into the desired 3D form through plastic deformation processing.

Surface Finishing

Improve appearance, enhance corrosion resistance, wear resistance or impart special functions.

Case Study of Processed Products

Professional Sheet Metal Fabrication Process - Precision, Efficiency, End-to-End Solutions

We possess mature sheet metal fabrication technology and a strict quality control system, providing you with efficient and reliable metalworking solutions from design support to finished product delivery.

1. Design & Engineering Support

Offer DFM (Design for Manufacturability) suggestions to optimize your drawings.

Perform precise flat pattern layout calculations to ensure accurate final dimensions.

Provide professional programming to prepare for efficient production.

2. Precise Blanking & Cutting

Core equipment: High-power laser cutters, CNC turret punch presses.

Capabilities: Accurately cut complex contours and holes; high material utilization; excellent edge quality.

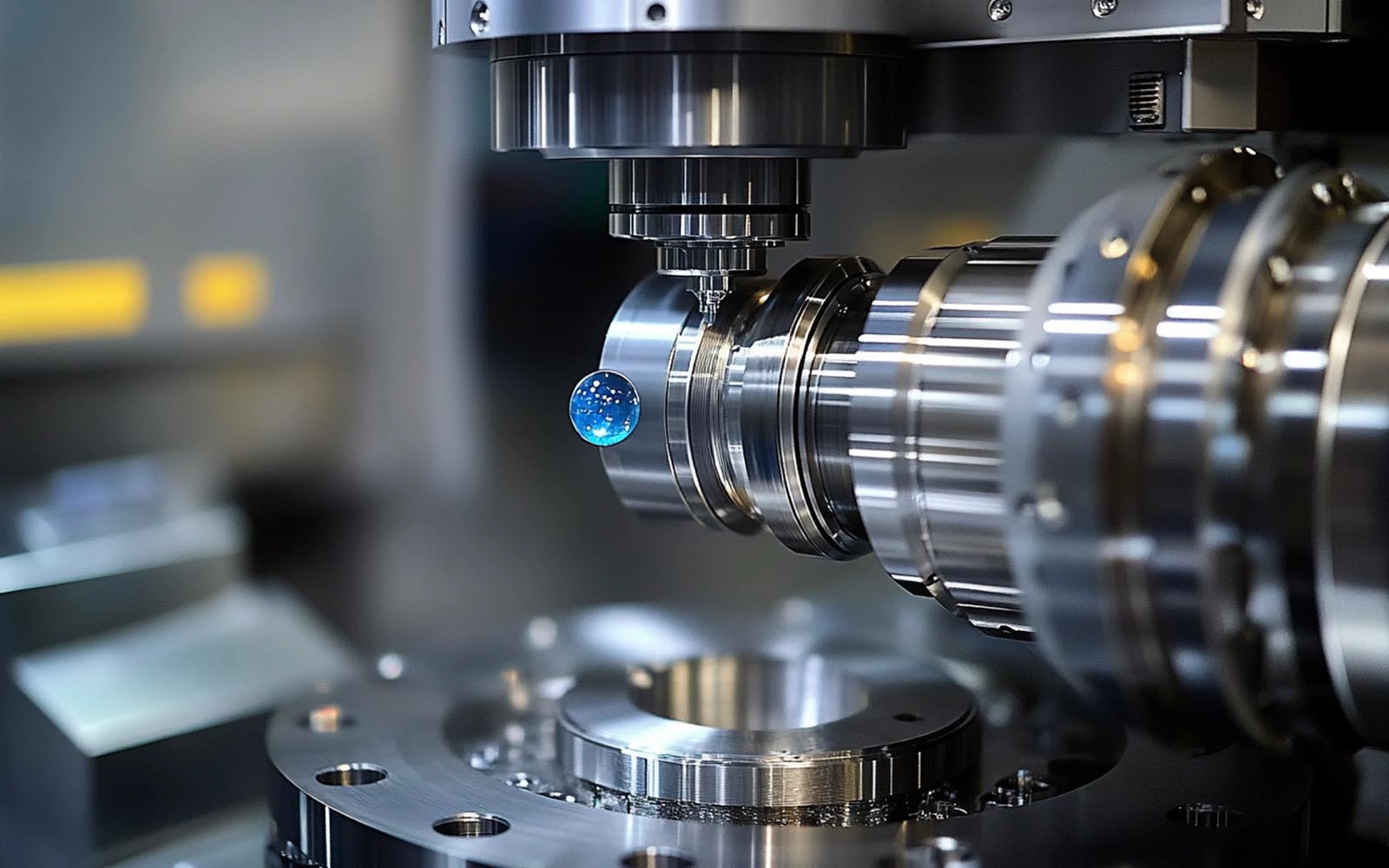

3. Efficient Forming

Core equipment: High-precision CNC press brakes.

Capabilities: Accurately bend various angles and shapes to accommodate complex structural requirements. Supports secondary forming processes like press riveting.

4. Reliable Joining & Assembly

Primary methods: Professional spot welding, MIG/TIG welding, laser welding; fastener connections (bolts, rivets, etc.).

Capabilities: Deliver robust and aesthetically pleasing joining solutions meeting diverse strength and appearance requirements.

5. Detailed Finishing

Deburring: Strictly remove burrs and sharp edges for safety and aesthetics.

Surface Treatment: Offer multiple options: painting (powder coating/spray painting), plating (electroplating), anodizing, etc., to enhance corrosion resistance, wear resistance, and appearance.

6. Stringent Quality Control

Implement multi-stage inspections (First Article Inspection, In-Process Inspection, Final Inspection) from raw materials to finished products. Guarantee every product meets your specifications and quality standards.

Common Materials for Sheet Metal Fabrication

The selection of sheet metal materials usually needs to consider the usage environment, functionality, cost, and appearance. Below are some commonly used materials. For more options, please consult us.

What Our Customers Say?

We undertake customized orders for military-grade UAV drive shafts, delivering 200 sets of finished products in 22 days. Our products are certified to China’s GJB 9001C Military Quality Management System, with zero failure rate during continuous operation under low temperature (-60℃) and high temperature (80℃) conditions.

German Customer: Customized UAV Drive Shafts

Their technical team provides a disruptive solution! By optimizing the transmission structure, the equipment accuracy is improved by 40%, and the whole process is debugged on site, and the technical support is an industry benchmark.

US Customer: Automation equipment upgrade cooperation

We customized 300 sets of precision laparoscopic forceps parts for a multinational medical group, completing the process from drawing optimization to finished product delivery in 18 days. The entire batch has passed ISO 13485 Medical Device Quality Management System certification, with dimensional tolerance controlled within ±0.005mm.