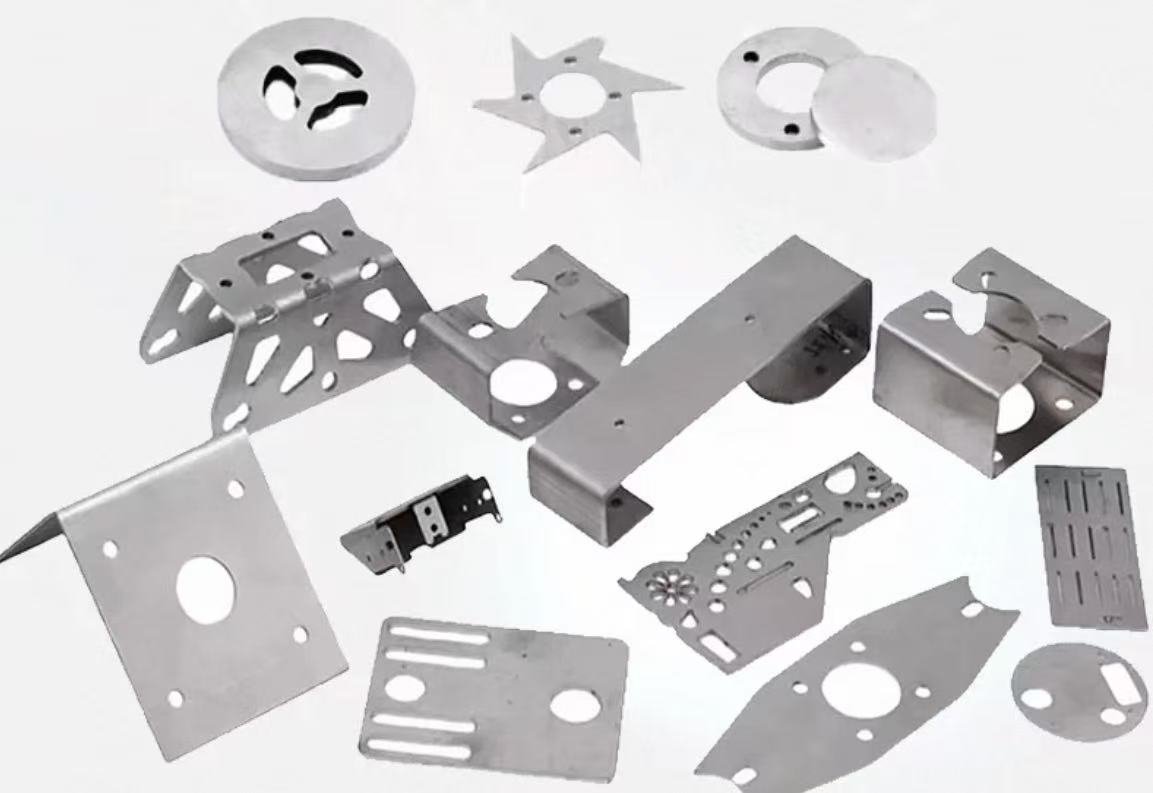

From the smooth curves of a smartphone body to the precision frame of a car chassis, and even the neat holes in a home appliance panel, these seemingly complex metal components are mostly created by the same “industrial magic” – the stamping process. As the “efficiency champion” of manufacturing, it uses the collision of “pressure” and “molds” to transform ordinary metal sheets into diverse shapes, supporting a vast industrial chain from daily necessities to aerospace equipment. Today, we’ll unlock its core logic and technical essence.

I. Stamping Process: The Technical Core Beyond “Pressing”

Stamping is not simply “extrusion deformation”. It applies pressure to metal blanks (mostly sheets, strips, tubes) via the power of a press and the contours of specialized molds, causing plastic deformation or separation to produce parts with specific shapes, sizes, and properties.

Its core advantage lies in the precise matching of “mold-material-force”: the mold acts as the “blueprint executor” with pre-carved details; the metal blank needs good plasticity; the press provides tens to tens of thousands of tons of pressure to shape the material. Unlike the “subtractive” machining, stamping is more like “additive shaping”, maximizing material performance and becoming the first choice for mass production.

II. Five Basic Processes: The “Deformation Ladder” of Stamped Parts

Any complex stamped part is a combination of five basic processes, creating infinite possibilities like building blocks.

1. Separation Process: Defining Material “Boundaries”

• Blanking: Cutting blanks from large metal sheets (e.g., initial car door shapes), whose precision lays the foundation for subsequent processing.

• Punching: Drilling holes in blanks (e.g., air conditioner heat dissipation holes), with hole diameter tolerance usually ≤ 0.1mm.

2. Forming Process: Turning Planes into “3D Shapes”

• Bending: Folding flat sheets into V/U shapes (e.g., toolbox edges), requiring precise angle control to avoid cracks and springback.

• Deep Drawing: Pressing into hollow parts (e.g., can bodies, car fuel tanks), demanding wrinkle-free surfaces and uniform wall thickness – a 0.05mm deviation leads to scrapping.

• Flanging: Creating upright edges around holes or at edges (e.g., nut threaded holes), enhancing part strength and assembly stability.

III. The “Ace Competitiveness” of Stamping Process

1. Crushing Efficiency: High-speed presses can complete 50-200 stampings per minute, with a daily output of tens of thousands of parts, suitable for mass production of automobiles and home appliances.

2. Cost-Friendly: Material utilization rate reaches 80%-95%, and molds can be reused tens of thousands of times – the larger the batch, the lower the unit cost.

3. High Performance: Metal grains are refined, making parts over 30% stronger than cast ones, with dimensional tolerance controllable within ±0.02mm.

IV. “Invisible Thresholds” Behind the Process

1. Mold: The “soul” of stamping. Precision molds require processing error ≤ 0.005mm, and their material and surface treatment affect service life and part quality.

2. Material: Needs good plasticity and toughness. Common materials include low-carbon steel, aluminum alloy, and stainless steel, each matching specific stamping pressure and mold design.

V. Future Trends: The “Evolution Direction” of Stamping

1. Precision Stamping: Achieves 0.001-0.01mm tolerance, e.g., 0.2-0.5mm pins for phone connectors with straightness error ≤ 2μm; medical catheter joints with sealing groove depth tolerance ±0.005mm to ensure airtightness.

2. Intelligent Stamping: Sensors collect real-time pressure and temperature data. When fluctuations exceed thresholds, parameters adjust automatically, reducing scrap rate from 3%-5% to below 0.5%. Wear-monitoring probes on molds trigger alerts when wear hits critical levels.

3. Composite Stamping: Integrates stamping with welding, painting, etc., enabling “one-time forming” to shorten production cycles.

From metal sheets to key components, stamping interprets manufacturing efficiency and precision with the “art of force”. Next time you touch a metal product, those neat folds and smooth curves are its “industrial marks”.